Overall Project Design

Project Description

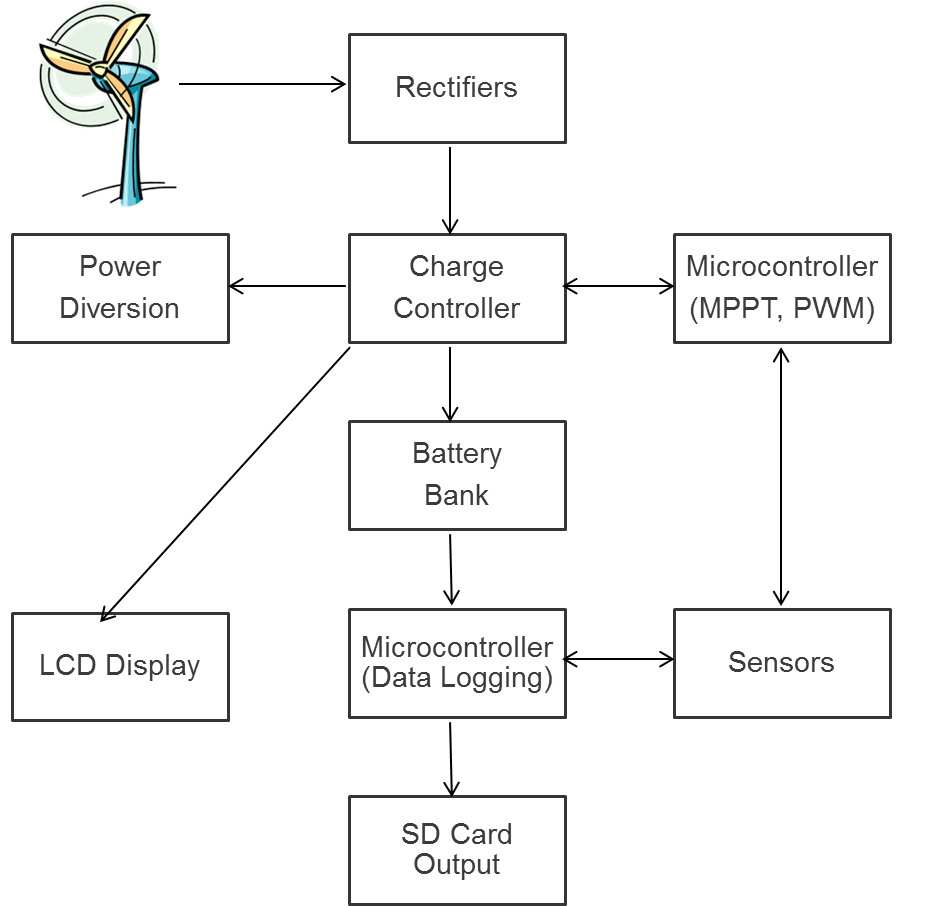

Intellaturbine runs on the principle of Maximum Power Point Tracking, the goal of which is to consistently adjust the current and voltage produced by the system until the highest efficiency of power generation is reached - i.e., the "Maximum Power Point". This is accomplished on the software level, but this functionality would not be possible without the DC-DC converter system. This system uses a buck regulator with high-tolerance components to accept input from the battery bank and MOSFETs, the latter of which enable the Pulse Width Modulation, a significant element in the Maximum Power Point Tracking algorithm.

The Intellaturbine system is capable of sensing the input and output voltages being asserted by the battery bank and turbine alternator via the sensing circuits consisting of low-pass filters and gain elements. This information is essential for not only power calculations within the MPPT algorithm, but for the LCD system. The LCD can provide the user with feedback on the current state of these variables at any time with a simple flick of a switch.

To best determine the conditions that enables consistent and efficient wind generation, the user may rely on the data logging subsystem. This system will use an anemometer in tandem with a real-time clock, support for SD/MMC input, and the sensing circuits to create periodic logs of wind speed and current/voltage with their own time stamps that are accurate to the second. Once the data is collected from the SD, it is easy for the user to open the resulting file in Excel and draw his own correlations between the prevailing wind speed and power produced.